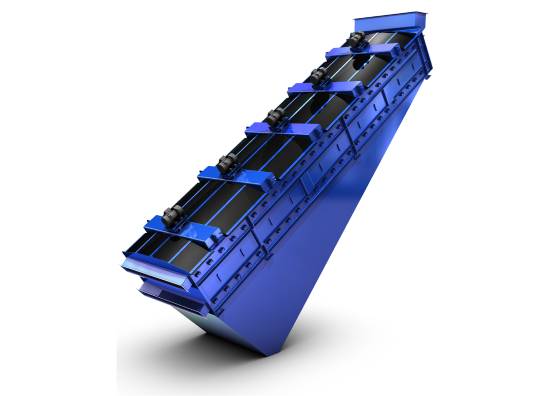

Linear Inclined Screener

What Is A Linear Inclined Screener?

The vibrating inclined screen is the most popular type of screen, due to its huge versatility and simplicity in design. The overwhelming majority of installations today are made up of numerous decks normally two or three, with single deck and four decks options available.

In its simplest form, the vibration of the screen media causes it to list and hence causes stratification of the product whilst the inclination and vibration combination provides the travel speed of the material over the deck.

Commonly used in scalping, the inclined screener removes finer particles before proceeding through the plant into machines such as crushers to help protect the crushers wear parts from abrasive or fine materials.

Inclined screeners are also used in classification with numerous decks to separate the screen media into different size categories as the product falls through the different apertures in the screen.

Commonly operating anywhere between 10-35 degrees in angle, inclined screeners rely upon gravity to move the media down the decks and across the mesh openings.

What Are The Benefits of Inclined Screening ?

Versatility

Inclined Screeners can be used in just about every stage of processing and numerous applications and have huge versatility due to their ability to change travel speed, mesh aperture, number of separations and angle of inclination.

Portable

Inclined screeners are available in lots of mobile options ideally prepared for changing work sites and changes in applications, especially when screening coarse elements.

High Production Capacities

Due to inclined screeners vibrating in circular motions this allows them to have increased processing rates.

Perfect For Bulky Coarse Materials

Heavier and bulkier materials that are often harder to travel through screen decks are perfectly suited for the inclined screener which utilises gravity and vibration to push the screen media down the decks.